Welcome to

Green Cotech: Your Zinc Coating Experts

Explore our comprehensive Turnkey Solutions for Zinc Flake Coating, ensuring longevity and durability for your products.

WHO WE ARE

Professional Coating services ready to collaborate.

With over 10 years of expertise in the Zn-Al Flake Coating Process, Green Cotech Pvt. Ltd. specializes in offering comprehensive solutions. Our services include Turnkey Projects, top-notch Equipment, and Technical Services, all featuring water-based chemistry for Zn-Al Flake Coating

Zinc Flake Coating

Zinc Al Flake Coating

Turnkey Solution for Zinc Flake Coating

OUR VALUE

Professional welder services ready to collaborate.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our Vision

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our Mission

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Associated with

ARCF is company with More than 7 Years in Zn-Al flake Coating Process; We provide turn key projects, Equipment’s & Technical Services, Solvent base and water base chemistry for Zn-Al Flake coating.

OUR SERVICES

Discover the excellence of our services, designed to meet your unique coating needs.

Zinc Flake Coating

Zinc Al Flake Coating

Turnkey Solution for Zinc Flake Coating

What is Zinc Flake Coating?

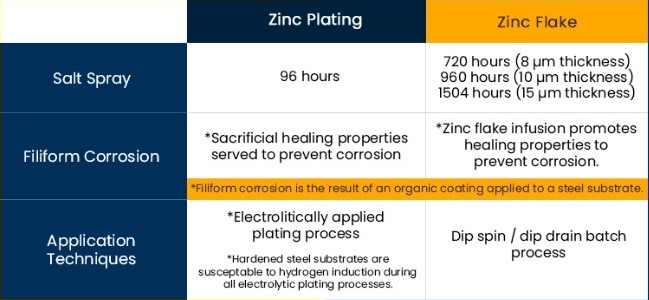

Zinc Flake Coating is a high-performance corrosion protection system based on a unique chemical formulation. These coatings are used to protect non-flexing or rarely- flexing parts like brake rotors, drums, callipers, brake lines, hose clamps, fuel tanks, clips, fasteners, springs, seat belts, door lock components and pretty much anything else that comes in contact with the elements and can survive a 450-degree curing cycle. These coatings can also prevent galvanic corrosion as a result of dissimilar metals coming in contact with each other.

OUR EQUIPMENT'S

Learn some new info about our latest equipment’s

Auto Dip-Spin Coating Machine DSTM-600

Auto Dip-Spin Coating Machine DSTM-450

How it works?

Discover the efficiency of Green Cotech’s coating process, where cutting-edge technology meets expertise to provide superior protection.

Barrier effect

The positioning of the zinc flakes gives the film a barrier effect that isolates the metal from the corrosive environment. Indeed the flake morphology increases the length of the path that the aggressive substances must travel to reach and corrode the substrate.

Sacrificial protection

When steel is coated with zinc flake, cathodic protection is achieved. Because of its lower electrochemical potential, compared to iron, zinc oxidizes preferentially: it “sacrifices” itself to protect the steel substrate.

Self Healing

The cathodic protection of zinc produces various kinds of salts (oxides, hydroxides, carbonates…), also known as “white rust”. Thanks to their mobility and adherence properties, these compounds heal the damaged areas of the coating and therefore act as a corrosion inhibitor to protect the substrate.

Adhesion to substrate

Our zinc flake sol-gel binders create strong covalent bonds with the substrate, which ensures excellent adhesion. In addition, at the interface, the migration of corrosion precursors (O2 and H2O) becomes more difficult, which reinforces the barrier effect of the coating.

COMMON QUESTIONS

Most Popular Questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Get in touch with Green Cotech for the best coatings

Make your things last longer and stay super safe!