Services

OUR SERVICES

We are here to manage your quality with experience

Green Cotech is emerging company involved into sourcing, developing and promoting Environmental friendly Green coating technologies for surface finishing industry in Automotive, Industrial and Engineering Construction field. We help to reduce environmental hazardous waste by avoiding hazardous declarable substances in process application engineering.

Experience : More than 10 Years in Zn-Al flake Coating Process; We provide turn key projects, Equipment’s & Technical Services, Solvent base and water base chemistry for Zn-Al Flake coating.

The products represented and sold by ARCF are environmental friendly by not using hazardous, pollutant and declarable substances like lead, chrome, cadmium and acids in formulations and processing. These coatings meet ELV, WEE and ROHS legislations for various applications. Following are some of the variety of products represented by ARCF.

Water based , organic/metallic/organometallic types of base coat and topcoats for enhancing the corrosion life on substrates We also provide, turnkey solutions for all types of dip spin based technologies such coating thickness.

WHAT WE OFFER

Partner with Us for Stronger Connections.

Zinc Flake Coating

Zinc Al Flake Coating

Turnkey Solution for Zinc Flake Coating

About Coating

What is Zinc Flake Coating?

Zinc Flake Coating is a high-performance corrosion protection system based on a unique chemical formulation. These coatings are used to protect non-flexing or rarely- flexing parts like brake rotors, drums, callipers, brake lines, hose clamps, fuel tanks, clips, fasteners, springs, seat belts, door lock components and pretty much anything else that comes in contact with the elements and can survive a 450-degree curing cycle. These coatings can also prevent galvanic corrosion as a result of dissimilar metals coming in contact with each other.

Understanding Different Coatings

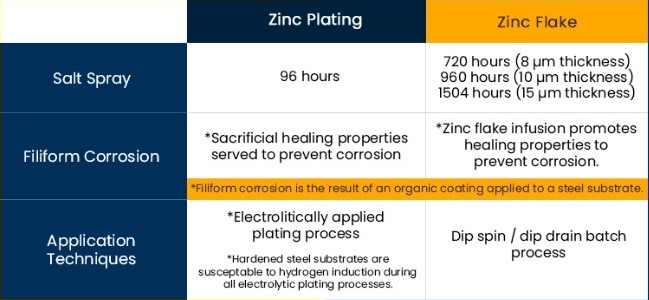

ZINC PLATING

Zinc plating-also referred to as

galvanization-employs an electrical current to facilitate the application of a thin coat of zinc to the surface of a metal component. The zinc oxidizes, creating a protective layer of zinc oxide that prevents the base metal from being exposed to the surrounding environment. It is largely used for iron or steel parts that would otherwise rust when exposed to air or water.

ZINC FLAKE COATING

Even the smallest components, such as nuts and bolts, must be adequately protected from corrosion to avoid compromising the integrity of the entire system or structure. Zinc flake coating is an ideal solution for these applications. When a zinc flake coated part is exposed to a corrosive compound, the zinc sacrifices itself to protect the base metal.

BENEFITS

BEST TURNKEY SOLUTION

IMPORTANCE OF EQUIPMENTS

The equipment used in the zinc flake coating process plays a crucial role in ensuring the effectiveness and quality of the coating application. Proper machinery is essential for achieving uniform and consistent coatings, adhering to industry standards, and preventing potential issues that could impact the coating’s performance.

If the equipment is not up to standard or poorly maintained, it can have several negative impacts:

- Inconsistent Coating Thickness

- Adhesion Problems

- Uneven Distribution of Zinc Flakes

- Reduced Coating Quality and Performance

- Productivity and Efficiency Issues

- Higher Costs

IMPORTANCE OF CHEMISTRY

Using the right chemicals and chemistry in zinc flake coating is crucial for optimal performance and durability. High-quality materials ensure uniformity, strong adhesion, and superior corrosion resistance. Investing in superior chemistry results in reliable and long-lasting coatings.

Using local chemistry in industrial processes, can have several significant disadvantages and negative consequences:

Reduced Quality and Performance.

- Uneven Distribution of Zinc Flakes

- Increased Maintenance and Rework

- Compliance & Environmental Issues

- Negative Impact on Machinery . Production Loss

PERFECTING THE PROCESS OF ZINC FLAKE COATING

In the ever-evolving market of chemical supply and distribution, the risk of encountering subpar local chemistry and poorly-manufactured equipment, sold at exorbitant prices, is alarmingly high. These inferior products can have a profoundly negative impact on the overall functioning of intricate processes such as zinc flake coating, a complex and emerging technology in India.

Adopting these inadequate materials not only disrupts the quality and efficiency of the coating process but can also lead to the wastage of valuable chemicals. Ultimately, this scenario inflates running costs, making the entire operation significantly more expensive.

We understand the nuances and challenges of this evolving technology. With the help of our partnerships contact with some of the best equipment manufacturers, and technical expertise we can help you master this process of Zinc Flake Coating further saving your costs.

SAMPLING

In ever-changing markets, it’s crucial to approve new technical methods. Our diverse team works closely and confidentially with you. We help design the right coatings for testing, apply them to your sample products, and then assess how well they perform.

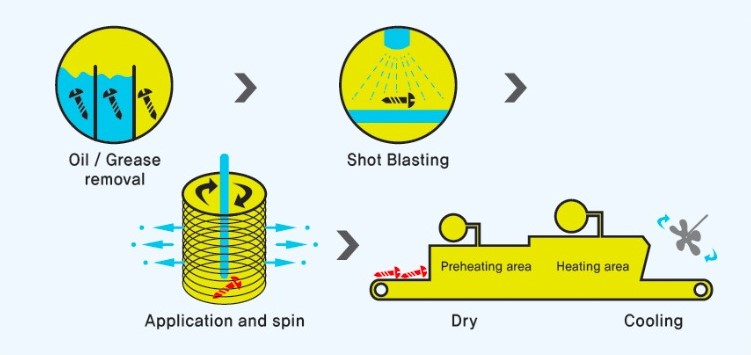

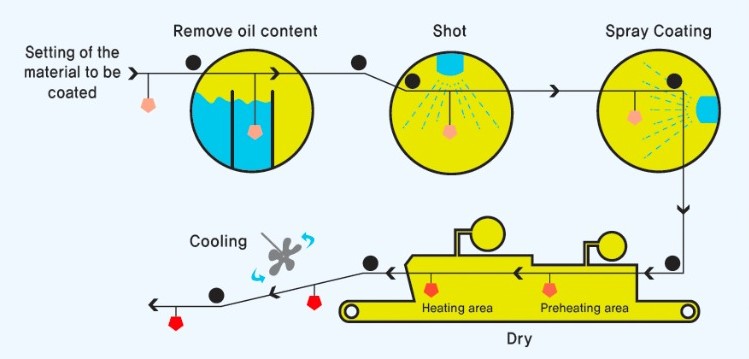

Process of Zinc Flake Coating

Zinc Rich and Zinc Flake products can be applied in Dip Spin, Dip Drain, and Spray systems, offering a wide choice of finish options depending on your project requirements for performance and cost. We offer’s the very best coatings from Premium Products INC, with many choices in primer/topcoat configurations to meet your special finishing needs.

Dip-spin method

A method appropriate for coating small articles such as bolts, nuts, clips, etc.

Spray method

A proper method for coating parts with wide surface area or parts where appearances area deemed important.

FAQ

Frequently Ask Questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.